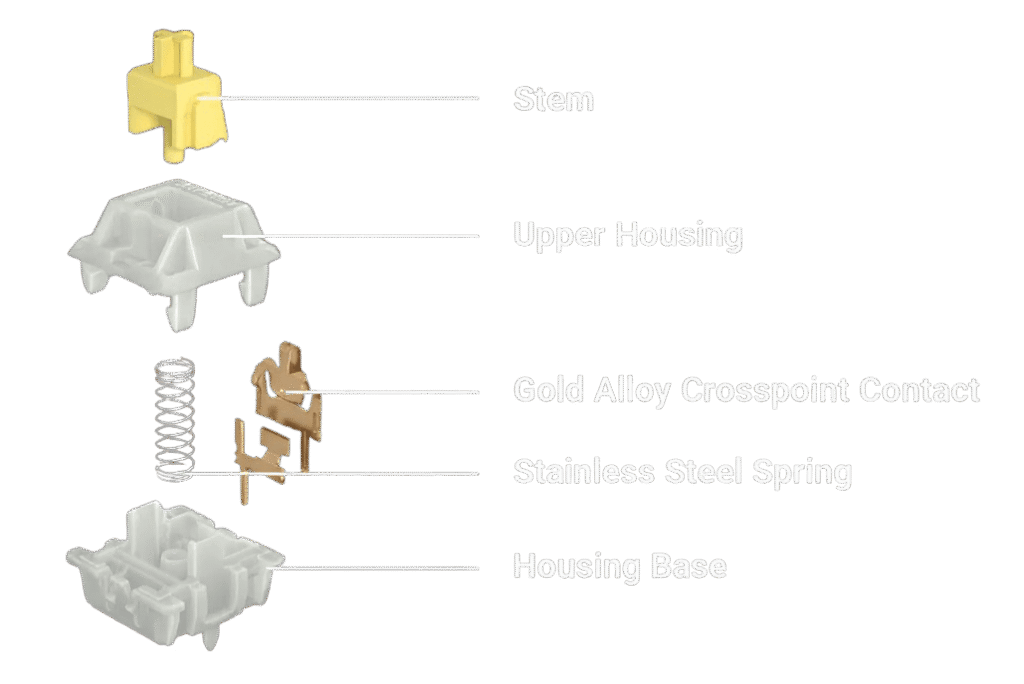

Keyboard switch leaves are the tiny metal parts inside a switch that make the key work. They’re usually made of copper or a copper alloy because it conducts electricity well. The leaves are basically two connected metal pieces. When you press a key, these leaves touch each other, completing the circuit. When you let go, they separate again, breaking the circuit. That’s how the keyboard knows when a key has been pressed.

These leaves might look small, but they’re a core part of the switch mechanism. Their quality directly affects how responsive and reliable the keyboard feels. High-quality switch leaves ensure accurate keypresses, while poor ones can lead to missed or faulty signals.

How switch leaves work

Inside a mechanical switch, the stem legs play a key role. They normally hold the two parts of the metal leaf apart, which keeps the circuit open. When you press a key, the stem legs move down and push the leaves together. Once the leaves connect, the circuit closes, and the signal is sent to your computer that’s how your keystroke gets registered.

When you release the key, the spring pushes the stem back up. This separates the leaves again, opening the circuit and resetting the switch so it’s ready for the next press.

This simple mechanism is what makes mechanical switches so reliable. Every press and release follows the same process, which is why gamers and typists alike trust them for accuracy and consistency.

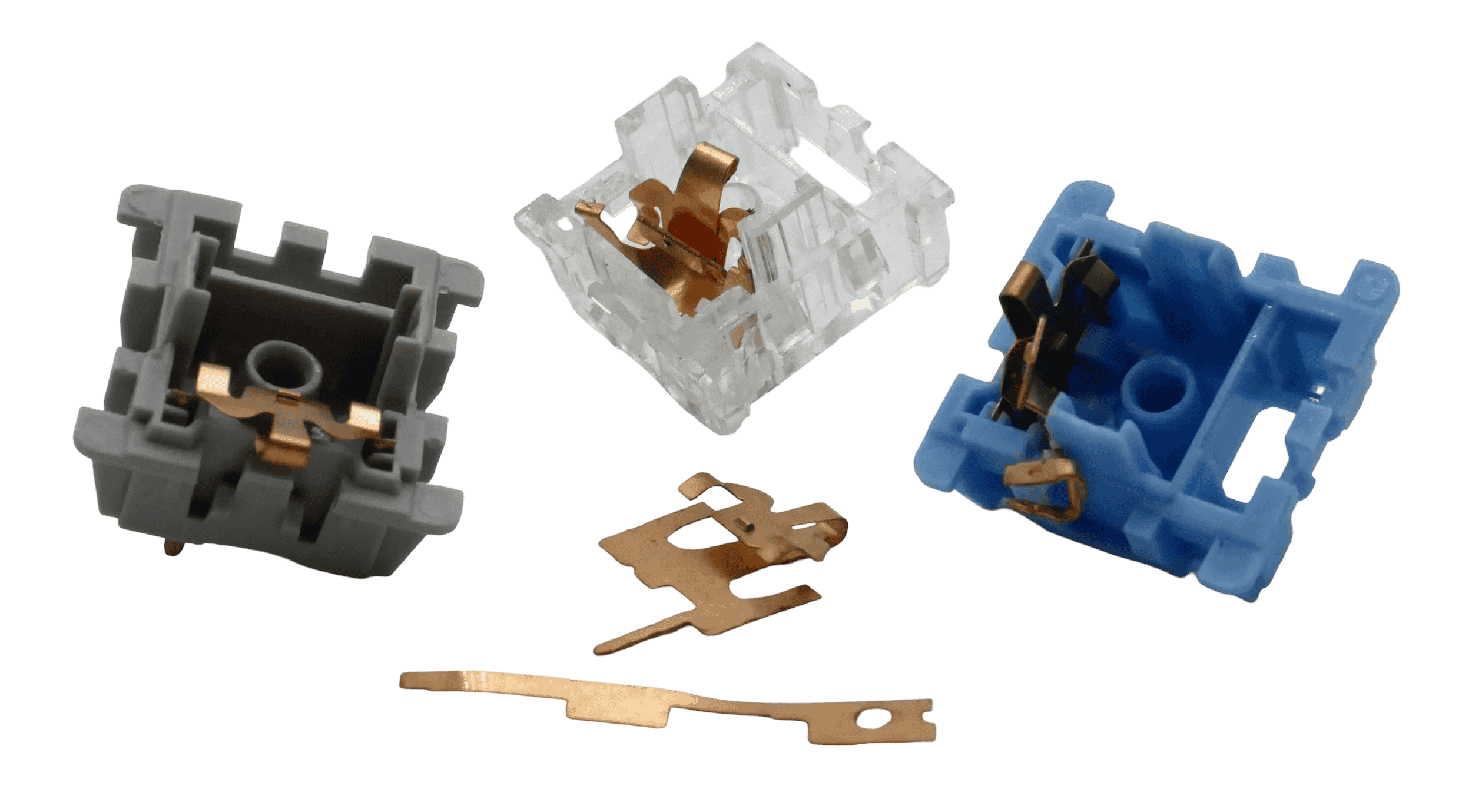

Types of Switches and Their Leaf Mechanisms

Linear Switches:

These switches give you a smooth keypress from top to bottom with no bump or click. They feel fast and consistent, which is why many gamers like them for quick reactions.

Tactile Switches:

These switches have a small bump when you press them down. That bump tells you the key has been activated, making them useful for typing since you don’t need to press all the way to the bottom.

Clicky Switches:

These switches are similar to tactile ones but add an audible click sound along with the bump. Some people love the satisfying sound and feedback, while others may find it too loud for shared spaces.

Hall Effect Switches:

Unlike traditional switches, these don’t use metal leaves or contacts. Instead, a magnet inside the stem interacts with a Hall effect sensor on the PCB to detect keypresses. This makes them extremely durable, smoother in performance, and they often allow for advanced features like adjustable actuation points.

Why Switch leaves are important

The design of the metal leaves plays a big role in how a switch feels, sounds, and responds while typing. They are responsible for making the electrical contact when you press a key, so if the leaves are damaged or bent, the switch may not work at all.

For a switch to function properly, the leaves need to be perfectly aligned and make clean contact every time. If they’re even slightly off, you can get issues like missed keystrokes, double presses, or an inconsistent typing feel.

This is why quality control in switch manufacturing is so important. Well-designed and well-aligned leaves give you reliable actuation, a smooth keypress, and a more enjoyable overall keyboard experience.

For a closer look at how those crisp, wear‑proof legends are made, explore our deep dive on What are Double Shot Keycaps?.