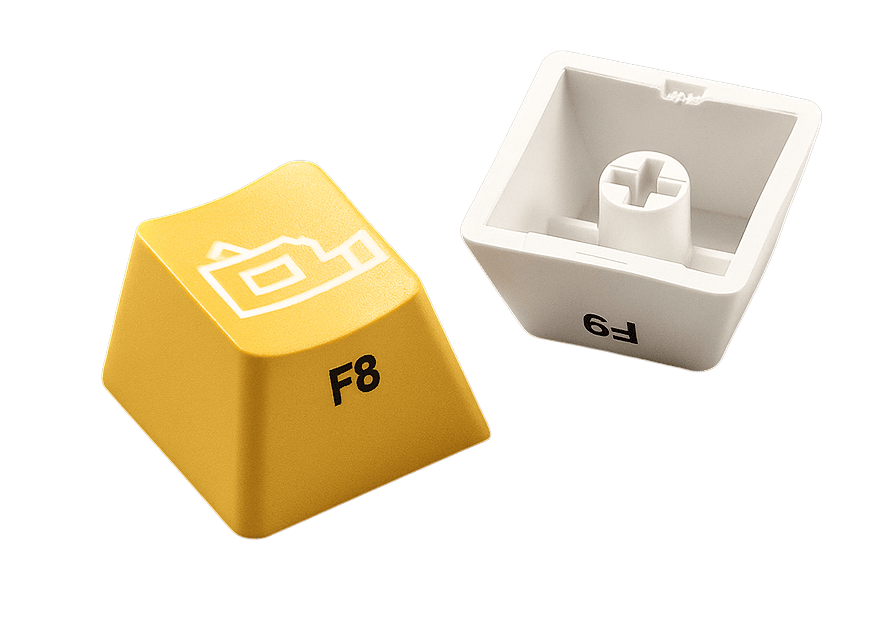

Double-shot keycaps are made using two separate pieces of plastic that are molded together through an injection molding process. This creates a single keycap where the legends (letters, numbers, or symbols) are permanent and never fade.

One piece of plastic forms the main body of the keycap, while the other creates the legend itself. Since the legend is part of the plastic and not just printed or painted on top, it stays sharp and clear even after years of use.

This is why double-shot keycaps are popular among mechanical keyboard users they’re durable, high quality, and long-lasting. On top of that, they often come with a premium feel and vibrant legends that look great, especially with backlighting.

The Process of Making Double Shot Keycaps

Double-shot keycaps are made using a two-layer molding process. The outer layer forms the overall shape of the keycap, while the inner layer creates the legend (the letter, number, or symbol on top). These two layers are joined together with a second injection of plastic, making the legend a permanent part of the keycap instead of something that can fade or rub off.

This process not only improves the longevity of the keycap but also gives it a more premium feel. The most commonly used plastics for double-shot keycaps are ABS and PBT. ABS is smoother and often used for brighter colors, while PBT is tougher and more resistant to wear.

Advantages of Double Shot Keycaps

The first big advantage of double-shot keycaps is their durability. Because of the way they’re built, they last much longer than printed or painted keycaps. You also get a solid and satisfying feel when typing, which helps with more precise keystrokes.

The second advantage is the legends. Since the legends are part of the plastic itself, they don’t wear off easily, even after years of use. This is a major reason people prefer double-shot keycaps over cheaper options.

On top of that, double-shot keycaps offer a consistent look and feel. The sharp, crisp legends add style to any mechanical keyboard, making it not only functional but also visually appealing.

Double Shot vs. Dye-Sublimated Keycaps

As explained earlier, double-shot keycaps are made of two layers: one layer forms the legend, and the other makes up the rest of the keycap.

On the other hand, dye-sublimated keycaps use a completely different process. Dye sublimation transfers the legend onto the PBT material using a mix of dye, heat, and pressure. This method is not the same as ordinary printing, where the ink quickly fades after a few months. Instead, sublimation embeds the dye deep into the plastic, making the legends last much longer.

The word “sublimation” refers to the process of turning a solid into gas without passing through the liquid state first. This is how the dye penetrates the keycap surface, bonding with it permanently. Because of this, dye-sublimated keycaps are known for durability, fade resistance, and sharp legends.

Why Gamers Prefer Double Shot Keycaps

Double-shot keycaps are especially popular among gamers because of their durable two-layer construction. They last longer than regular printed keycaps and hold up well even after years of heavy use. The premium build gives them a solid, high-quality feel that makes them a reliable choice for gaming.

One of the most important things about double-shot keycaps is the typing experience. They provide a crisp, precise keystroke that feels satisfying whether you’re typing or gaming. The sharp, permanent legends also make it easier to see your keys during intense sessions, so you don’t have to worry about fading over time.

Conclusion

If you’re thinking about upgrading your keyboard with double-shot keycaps, it’s a smart move. They not only improve performance but also give your keyboard a fresh, stylish look. These keycaps are built to last, so you don’t have to worry about the legends fading or the plastic wearing out.

Durability is one of their biggest strengths, making them perfect for people who type a lot or game for long hours. On top of that, double-shot keycaps deliver a solid and comfortable typing feel, which makes every keystroke more satisfying.

So, whether you want your keyboard to look better, feel better, or simply last longer, double-shot keycaps are one of the best upgrades you can make.

FAQ’S

Do double shot keycaps sound better?

Double shot keycaps produce a deeper and more refined sound compared to thin single-layer keycaps. This makes typing feel more solid and satisfying, which is why many people prefer them.

What is the difference between single shot and double shot keycaps?

The main difference between single shot and double shot keycaps is in durability. Single shot keycaps are fairly strong but their legends can fade over time. Double shot keycaps, on the other hand, keep their legends clear and sharp forever because the letters are molded into the plastic, not just printed on top.

What is a pudding key?

Pudding keycaps are known for their dual-layer design. The sides are translucent, which lets RGB lighting shine through, while the top stays opaque for clear and readable legends. This design makes keyboards look brighter and more colorful.

What does PBT stand for in keycaps?

PBT stands for Polybutylene Terephthalate, a type of thermoplastic known for its strength and durability. PBT keycaps resist shine, keep their textured matte finish, and last much longer than cheaper plastic options like ABS.

Want to understand what happens beneath each cap? Dive into our breakdown of Keyboard Switch Leaves Explained.